残极破碎机

残极破碎机-张家港长力机械有限公司

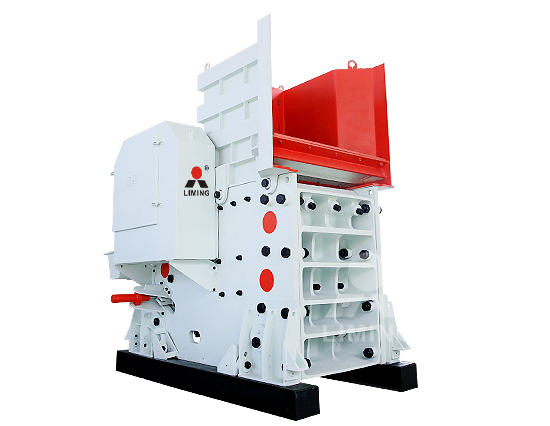

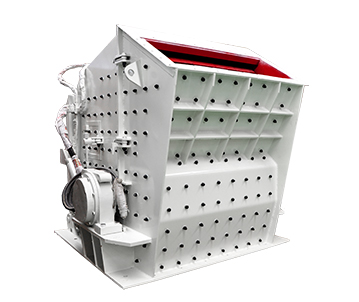

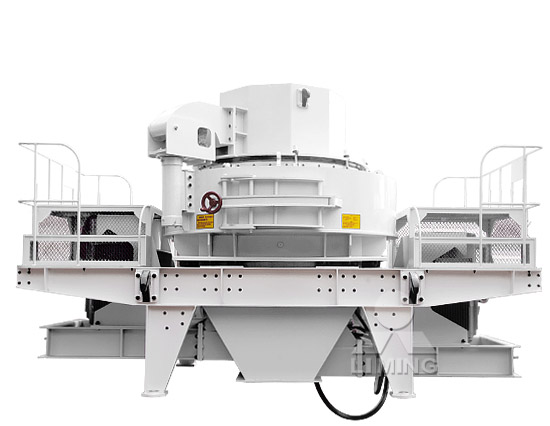

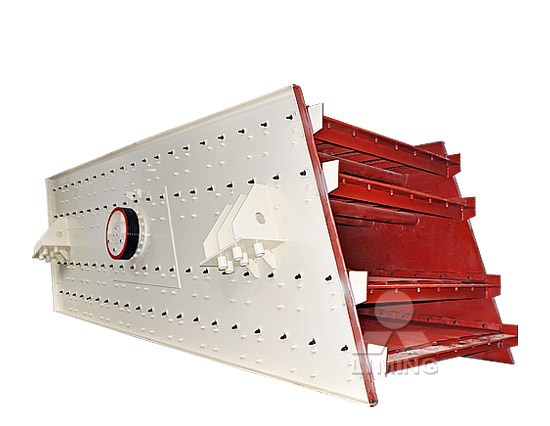

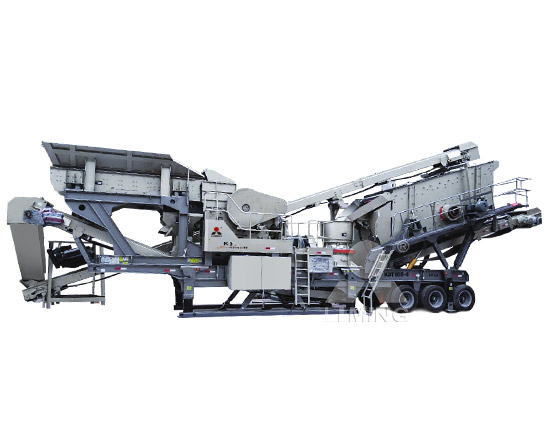

残极破碎机是用来破碎从阳极钢爪上压脱下来的残极块以及其它不合格的生、熟阳极块的设备,也可用于碳素厂破碎生、熟废电极及阴极碳块。. 目前国内市场上生产的型号普遍 残极破碎机适用于抗压强度小于300Mpa,进料粒度小于80mm、成品粒度要求50目-20mm,水份小于35%的固体物料的中碎和细碎作业,高铬锰钢含稀有金属材质的辊 残极破碎机,残极破碎机价格_华盛铭破碎机厂家500t液压残极破碎机为我公司结合其他行业压力机的优点自主研发的产品。 该设备采用PLC电液自动控制,使系统的响应快,控制精度高,工作安全可靠,无需润滑,无下沉 HP-CBC系列液压残极破碎机_报价-山东华鹏精机股份有限 ...

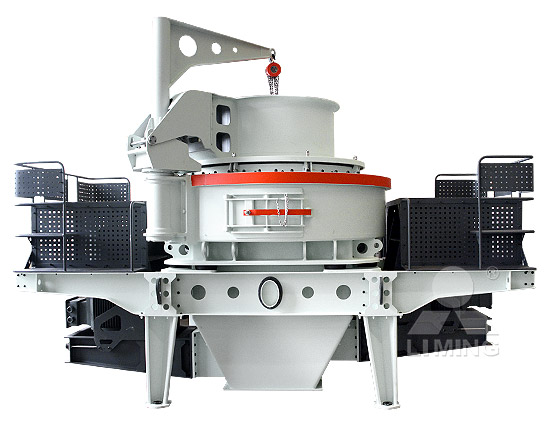

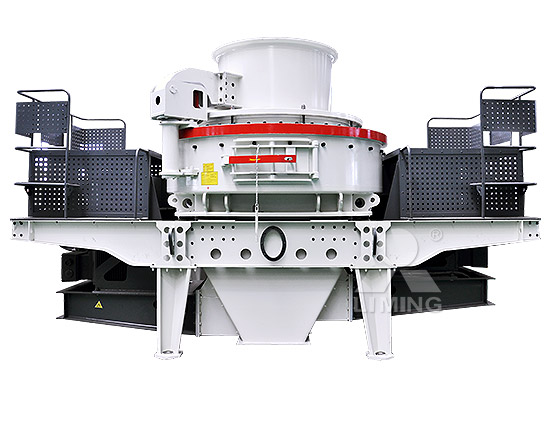

残极破碎机的原理_中国矿机基地

残极破碎机的原理圆锥破碎机破碎比大、效率高、能耗低,产品粒度均匀,适合中碎和细碎各种矿石,岩石。广泛运用于大山的矿山、冶炼、公路、建材、铁路和美化学工业等众多 500吨残阳破碎机是用挤压的方法将废弃的阳极块或碳棒破碎以再利用的一种破碎机器。 [1] 随着铝电解、电炉炼钢、化工磷硫业和其他电冶金行业的发展,碳素工业已经成为国民 阳极(残极)破碎机的设计--说明书 - 百度文库残极破碎机何为残极碎石机呢? 残级型是电解铝用最阳极生产中的一台重要设备,其作用是交阳极生产中的残次阳极埠破碎后与旨极原料混合后再次利用。残极破碎机_中国矿机基地

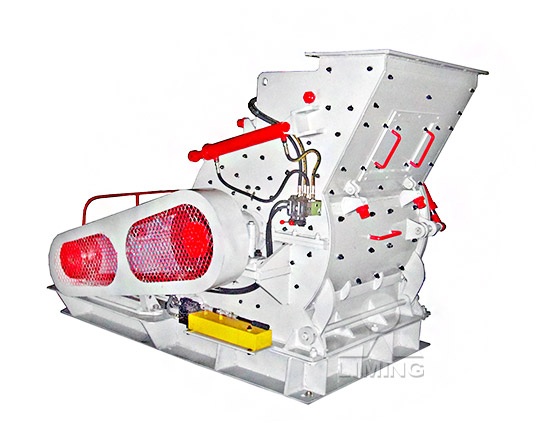

HP-CBC系列液压残极破碎机-参数-价格-中国粉体网

500t 液压残极破碎机为我公司结合其他行业压力机的优点自主研发的产品。 该设备采用 PLC 电液自动控制,使系统的响应快,控制精度高,工作安全可靠,无需润滑,无下沉现象。HP-CBC液压残极破碎机. 应用于预焙阳极、阴极、石墨电极等炭素制品的废料、残极等的破碎处理。 液压性能优异,破碎效率高;采用PLC电液自动控制,系统反应快,控制精度 公司介绍 - HWAPENG冷轧管机. 其它冶金设备. 冷床. 焦炉机械. 环保设备. 除尘器. 垃圾焚烧设备. 医疗垃圾焚烧尾气净化装置. 其它设备. 船用设备海工产品. 核电产品. 残极破碎机. 其它设备. 压力容器. 塔 残极破碎机-产品分类-张家港长力机械有限公司

CN112191184A ... - Google Patents

CN112191184A CN202011032669.0A CN202011032669A CN112191184A CN 112191184 A CN112191184 A CN 112191184A CN 202011032669 A CN202011032669 A CN 202011032669A CN 112191184 A CN112191184 A CN 112191184A Authority CN China Prior art keywords lithium ion ion battery negative electrode battery negative electrode US4585538A US06/638,891 US63889184A US4585538A US 4585538 A US4585538 A US 4585538A US 63889184 A US63889184 A US 63889184A US 4585538 A US4585538 A US 4585538A Authority US United States Prior art keywords cleaning bath material residual anode residual striker bodies Prior art date 1983-08-17 Legal status (The legal status is US4585538A - Google PatentsCN107366008A CN201710805704.XA CN201710805704A CN107366008A CN 107366008 A CN107366008 A CN 107366008A CN 201710805704 A CN201710805704 A CN 201710805704A CN 107366008 A CN107366008 A CN 107366008A Authority CN China Prior art keywords cleaning rotating shaft broken fixedly connected mobile holder Prior CN107366008A - 残极清理机 - Google Patents

CN218689872U - 一种混凝土破碎装置 - Google Patents

CN218689872U CN202222884257.0U CN202222884257U CN218689872U CN 218689872 U CN218689872 U CN 218689872U CN 202222884257 U CN202222884257 U CN 202222884257U CN 218689872 U CN218689872 U CN 218689872U Authority CN China Prior art keywords clamp plate concrete shell rack broken wheel Prior art date 2022-10 CN105413841A CN201510920006.5A CN201510920006A CN105413841A CN 105413841 A CN105413841 A CN 105413841A CN 201510920006 A CN201510920006 A CN 201510920006A CN 105413841 A CN105413841 A CN 105413841A Authority CN China Prior art keywords charcoal block broken charcoal bunker lift crusher discharging CN105413841A - 一种炭块破碎输送系统 - Google PatentsCN105413841B CN201510920006.5A CN201510920006A CN105413841B CN 105413841 B CN105413841 B CN 105413841B CN 201510920006 A CN201510920006 A CN 201510920006A CN 105413841 B CN105413841 B CN 105413841B Authority CN China Prior art keywords carbon block bunker lift broken crusher shape Prior art date 2015-12 CN105413841B - 一种炭块破碎输送系统 - Google Patents

CN221200629U - Google Patents

CN221200629U CN202322449973.0U CN202322449973U CN221200629U CN 221200629 U CN221200629 U CN 221200629U CN 202322449973 U CN202322449973 U CN 202322449973U CN 221200629 U CN221200629 U CN 221200629U Authority CN China Prior art keywords fixedly connected wall top surface simulation fixed box Prior art date CN106697761A CN201510793033.0A CN201510793033A CN106697761A CN 106697761 A CN106697761 A CN 106697761A CN 201510793033 A CN201510793033 A CN 201510793033A CN 106697761 A CN106697761 A CN 106697761A Authority CN China Prior art keywords pusher arm material pusher main body polar plate stage material Prior CN106697761A - 一种蓄电池用铅极板包板机推料器 - Google ...US4585538A US06/638,891 US63889184A US4585538A US 4585538 A US4585538 A US 4585538A US 63889184 A US63889184 A US 63889184A US 4585538 A US4585538 A US 4585538A Authority US United States Prior art keywords cleaning bath material residual anode residual striker bodies Prior art date 1983-08-17 Legal status (The legal status is US4585538A - Google Patents

CN201943731U - 一种液压支架底座腔体结构 - Google Patents

CN201943731U CN2011200480053U CN201120048005U CN201943731U CN 201943731 U CN201943731 U CN 201943731U CN 2011200480053 U CN2011200480053 U CN 2011200480053U CN 201120048005 U CN201120048005 U CN 201120048005U CN 201943731 U CN201943731 U CN 201943731U Authority CN China Prior art keywords CN110558571B CN201910919792.5A CN201910919792A CN110558571B CN 110558571 B CN110558571 B CN 110558571B CN 201910919792 A CN201910919792 A CN 201910919792A CN 110558571 B CN110558571 B CN 110558571B Authority CN China Prior art keywords walnut spring shell breaking shell groups Prior art date 2019-09-27 CN110558571B - 一种核桃破壳收集装置及使用方法 - Google ...US4585538A US06/638,891 US63889184A US4585538A US 4585538 A US4585538 A US 4585538A US 63889184 A US63889184 A US 63889184A US 4585538 A US4585538 A US 4585538A Authority US United States Prior art keywords cleaning bath material residual anode residual striker bodies Prior art date 1983-08-17 Legal status (The legal status is US4585538A - Google Patents

CN106362826A - 煤块破碎机 - Google Patents

CN106362826A CN201611050823.0A CN201611050823A CN106362826A CN 106362826 A CN106362826 A CN 106362826A CN 201611050823 A CN201611050823 A CN 201611050823A CN 106362826 A CN106362826 A CN 106362826A Authority CN China Prior art keywords connecting rod briquetting coal pressing plate base Prior art date 2016 CN107499350B CN201710465041.1A CN201710465041A CN107499350B CN 107499350 B CN107499350 B CN 107499350B CN 201710465041 A CN201710465041 A CN 201710465041A CN 107499350 B CN107499350 B CN 107499350B Authority CN China Prior art keywords barrel car body discharge nozzle wheel lever Prior art date 2017-06 CN107499350B - 一种混凝土供料车 - Google PatentsUS4585538A US06/638,891 US63889184A US4585538A US 4585538 A US4585538 A US 4585538A US 63889184 A US63889184 A US 63889184A US 4585538 A US4585538 A US 4585538A Authority US United States Prior art keywords cleaning bath material residual anode residual striker bodies Prior art date 1983-08-17 Legal status (The legal status is US4585538A - Method and apparatus of cleaning residual

CN210151178U - Google Patents

CN210151178U CN201920628032.4U CN201920628032U CN210151178U CN 210151178 U CN210151178 U CN 210151178U CN 201920628032 U CN201920628032 U CN 201920628032U CN 210151178 U CN210151178 U CN 210151178U Authority CN China Prior art keywords discharging device plate device body adjusting screw steel rolling 본 발명은 암석, 석탄 등을 분쇄하는 크러셔에 관한 것으로서, 더욱 구체적으로는 폐 레일을 이용한 크러셔에 관한 것이다. 본 발명은 본체부(101), 걸이부(110), 지지부(120)를 포함하는 회전본체(100) 및, 분쇄자(200)를 포함하는 크러셔를 제공한다. 또한 본 발명은 상기한 분쇄자는 연결부(210), 타격부(220 ...KR20160107565A - 폐 레일을 이용한 크러셔 - Google PatentsCN107421325A CN201610342392.9A CN201610342392A CN107421325A CN 107421325 A CN107421325 A CN 107421325A CN 201610342392 A CN201610342392 A CN 201610342392A CN 107421325 A CN107421325 A CN 107421325A Authority CN China Prior art keywords alloy ball automatic separating apparatus push pedal chute feeder CN107421325A - Google Patents

CN207267891U - 一种熔铅系统 - Google Patents

CN207267891U CN201720713984.7U CN201720713984U CN207267891U CN 207267891 U CN207267891 U CN 207267891U CN 201720713984 U CN201720713984 U CN 201720713984U CN 207267891 U CN207267891 U CN 207267891U Authority CN China Prior art keywords lead feed back storehouse melting furnace sink Prior art date 2017-06 CN211942265U CN201921977142.8U CN201921977142U CN211942265U CN 211942265 U CN211942265 U CN 211942265U CN 201921977142 U CN201921977142 U CN 201921977142U CN 211942265 U CN211942265 U CN 211942265U Authority CN China Prior art keywords hopper sides oil press lifter oil Prior art date 2019-11-15 Legal status CN211942265U - 榨油机的上料装置 - Google Patents